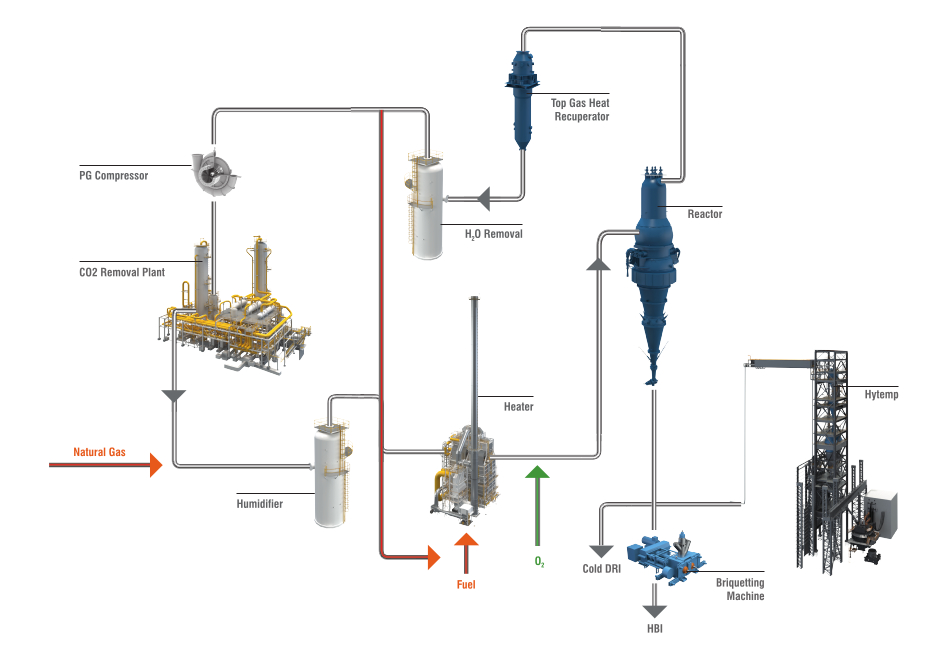

The ENERGIRON® ZR (Zero Reformer) Process scheme is the latest achievement in reducing the size and improving the efficiency of direct reduction plants. The process is feed by NG and reducing gases are generated by in-situ reforming within the reduction reactor with no need for the Reformer. The Fe° contained in the DRI produced by the process itself acts as the necessary, renewable and continuous catalyst for the reforming of CH4 into H2+CO.

Other gases such as hydrogen, syngas and coke-oven gas, among others, can also be used as reducing agents, depending on local availability and economics. In any case, the same basic process scheme is used regardless of the reducing gas source.

A distinct advantage of the ENERGIRON® ZR technology is the wider flexibility for DRI carburization according to the steelmaking requirements. DRI carbon levels up to 5% can be obtained, due to the prevailing conditions of high methane (CH4) concentration in the process gas introduced into the reactor and the high temperature of the bed (>860°C), which favors the diffusion of Carbon into the Iron matrix and the precipitation of Iron Carbide (Fe3C) in the DRI product.