ENERGIRON® is the DR technology that provides the lower DRI production cost and the highest quality of DRI.

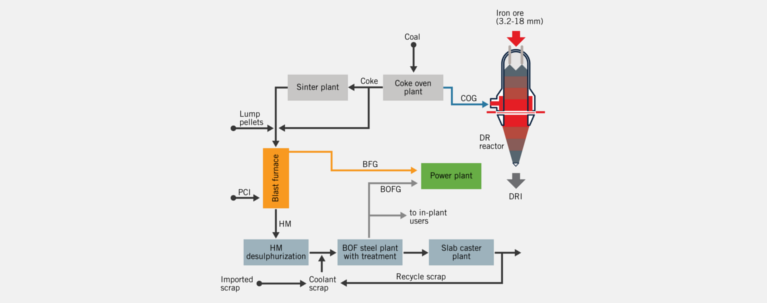

The ENERGIRON® plants can operate within a variety of conditions, using the resources locally available at the most competitive price. Different grades of iron ores can be used, including BF pellets up to 100%. The reducing agent can be either natural gas, reformed gas, coke oven gas, hydrogen, naphtha or a mixture of the same. In this way, OPEX can be further reduced and plant managers have the possibility to adjust the feedstock strategy based on the actual market trends.

IRON ORE

The ENERGIRON® technology is designed to operate with a large range of commercially available DR- grade-iron ores, both in pellet and lump ore form.

REFORMED GAS | SYNGAS | COG

Of course, ENERGIRON® plants can also use the conventional steam-natural gas reforming equipment, which has long characterized the process.

CONSUMPTIONS

As compared to other DR process, the DRI and steel production costs through the ENERGIRON® Process is lower